Hello! Welcome to the official website of Rongsheng Precision Technology (Shenzhen) Co., Ltd.!

Equipments

-

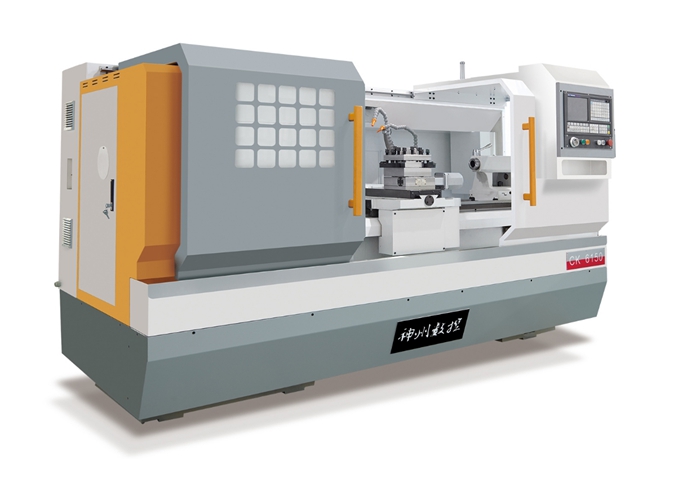

CNC-Lathing lathe

CNC-Lathing lathe -

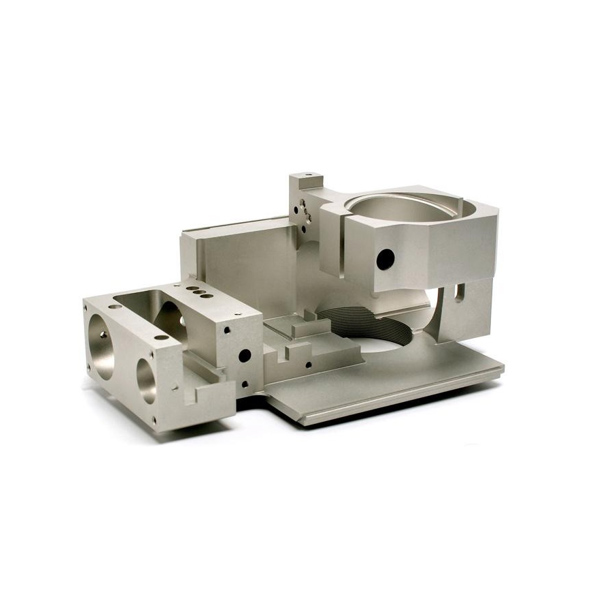

Vertical machining center (3-axis)The precision mechanical parts processed by Rongsheng Precision Technology (Shenzhen) Co., Ltd. are used in the assembly of automobile automation machines. The entire company implements the policy of not producing defects or leaking defects, and all products are 100% inspected and shipped. Provide Germany, Japan...

Vertical machining center (3-axis)The precision mechanical parts processed by Rongsheng Precision Technology (Shenzhen) Co., Ltd. are used in the assembly of automobile automation machines. The entire company implements the policy of not producing defects or leaking defects, and all products are 100% inspected and shipped. Provide Germany, Japan... -

Vertical machining center (5-axis)The precision mechanical parts processed by Rongsheng Precision Technology (Shenzhen) Co., Ltd. are used in the assembly of automobile automation machines. The entire company implements the policy of not producing defects or leaking defects, and all products are 100% inspected and shipped. Provide Germany, Japan...

Vertical machining center (5-axis)The precision mechanical parts processed by Rongsheng Precision Technology (Shenzhen) Co., Ltd. are used in the assembly of automobile automation machines. The entire company implements the policy of not producing defects or leaking defects, and all products are 100% inspected and shipped. Provide Germany, Japan... -

Laser cuttingThe precision mechanical parts processed by Rongsheng Precision Technology (Shenzhen) Co., Ltd. are used in the assembly of automobile automation machines. The entire company implements the policy of not producing defects or leaking defects, and all products are 100% inspected and shipped. Provide Germany, Japan...

Laser cuttingThe precision mechanical parts processed by Rongsheng Precision Technology (Shenzhen) Co., Ltd. are used in the assembly of automobile automation machines. The entire company implements the policy of not producing defects or leaking defects, and all products are 100% inspected and shipped. Provide Germany, Japan...

4 reasons to choose us

01

Craftsman spirit, striving for excellence

Company founder engaged in precision machining for more than 20 years,

With more than 10 technicians engaged in precision machining for more than 20 years,

Provide technical consulting and technical exchange.

2

Customer first, attentive service

Provide quotations and consultations online 24 hours every day,

sample,low-volume,mass production are produced.

3

Efficient production and fast delivery

3~7 days for samples, 7~10 days for batch delivery.

Shipped by domestic or international well-known logistics Shunfeng, DHL, UPS, etc..In emergency circumstances,drive delivery for local customers.

4

Quality likes life, product is character

70% of new customers come from old clients.

Produced the precision mechanical workpiece as Japanese quality.

Can correspond to Chinese/Japanese/English multilingual drawings.

Quality Assurance

No production defects, no defective outflows, all products are 100% fully inspected and shipped.

- Equipments

About us

Rongsheng Precision is a prototype and customized parts manufacturing factory. Our services have CNC machining (metal and plastic), sheet metal,steel mold,rapid injection molding,3D printing,die casting parts and surface treatment.

With more than 90 sets processing equipment--advanced CNC machining centers (3/4/5 axis), EDM, SLS, SLA rapid prototyping machines, large laser cutting machines and special-shaped sheet metal production machines .And equipped with coordinate-measuring machine, two-dimensional projector,altimeter and other measuring tools to ensure the product quality.

News

Deliver cutting-edge information and grasp industry trends

Company news /

More+

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

Industry information /

More+

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】

-

Before it emerged, the development of many products was not as convenient as it is today. We know that a large amount of money is invested in mold opening and production. If something goes wrong, the loss will be huge. Now with the service of , as long as you have 3D processing drawings, everything becomes very simple. For example, before mass production of electrical products, they usually find a supplier to process CNC parts and make a model first so that they can be inspected.【Detailed】