How to CNC machining of nylon parts?

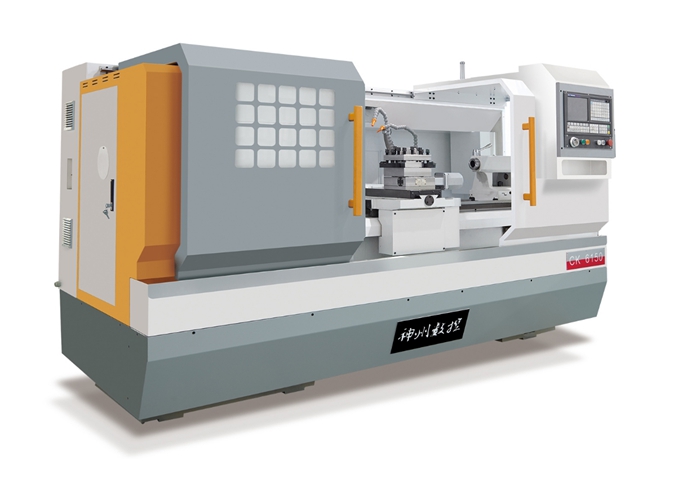

As usual, almost all plastic parts are pretty much the same when it comes to CNC machining. We will machine nylon parts using CNC milling and a lathe or lathe depending on the different geometries of the part size.

What are the characteristics of CNC machining of nylon parts? CNC machining of nylon parts

Light weight, good wrinkle resistance, good breathability, durability, dyeability and heat setability. Therefore, it is considered one of the very promising materials.

Especially now, CNC machined nylon parts have been widely used in different industries. It is even an excellent and important plastic engineering material that can replace steel, iron and other metal materials.

Machinery, chemical industry, instrumentation, automobile, medical treatment, construction, etc.

Advantages of CNC machining of nylon parts

CNC machining of medical parts in mechanical and automotive fields

PA-based materials have the characteristics of non-toxic, light weight, excellent mechanical strength, wear resistance and corrosion resistance. Therefore, PA parts are widely used to replace metals: such as replacing copper to manufacture some bearings, gears, pumps and other parts in machinery, chemical industry, instrumentation, automobile and other industries.

PA is easy to melt spin and has high strength. It is mainly a synthetic fiber and can be used as medical suture. Usually we have two processes for making it, CNC processing and injection molding.

PA is used to make ropes, industrial fabrics, cables, conveyor belts, tent nets, etc., and is also mainly used in parachutes and other national defense military fabrics.

Of course, PA materials are also used in the injection molding field. It is a very good engineering material for many industries such as aerospace, automotive, electronic applications, customer products, etc.