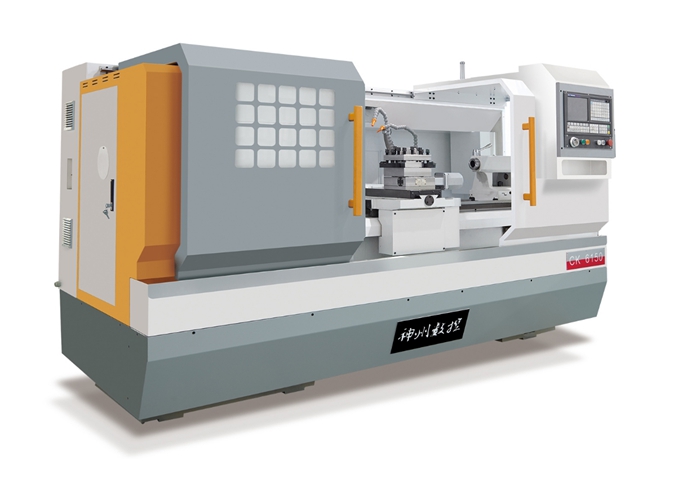

Sheet metal

Sheet metal parts

Sheet metal is to plastically deform some metal sheets by hand or die stamping to form the desired shape and size, and can further form more complex parts through welding or a small amount of mechanical processing. Usually, the most important aspect of the sheet metal process is The four steps are shearing, punching/cutting/folding/rolling, welding, surface treatment, etc.

Consultation